Portable, super-high-resolution 3D imaging

09 Aug 2011

By combining a clever physical interface with computer-vision algorithms, researchers in MIT's Department of Brain and Cognitive Sciences have created a simple, portable imaging system that can achieve resolutions previously possible only with large and expensive lab equipment. The device could provide manufacturers with a way to inspect products too large to fit under a microscope and could also have applications in medicine, forensics and biometrics.

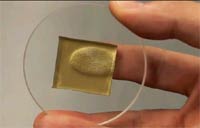

The heart of the system, dubbed GelSight, is a slab of transparent, synthetic rubber, one of whose sides is coated with a paint containing tiny flecks of metal. When pressed against the surface of an object, the paint-coated side of the slab deforms. Cameras mounted on the other side of the slab photograph the results, and computer-vision algorithms analyse the images.

The heart of the system, dubbed GelSight, is a slab of transparent, synthetic rubber, one of whose sides is coated with a paint containing tiny flecks of metal. When pressed against the surface of an object, the paint-coated side of the slab deforms. Cameras mounted on the other side of the slab photograph the results, and computer-vision algorithms analyse the images.

In a 2009 paper, Edward Adelson, the John and Dorothy Wilson Professor of Vision Science and a member of the Computer Science and Artificial Intelligence Laboratory, and Micah Kimo Johnson, who was a postdoc in Adelson's lab at the time, reported on an earlier version of GelSight, which was sensitive enough to detect the raised ink patterns on a $20 bill.

At this year's Siggraph - the premier conference on computer graphics - Adelson and Johnson, along with graduate student Alvin Raj and postdoc Forrester Cole, are presenting a new, higher-resolution version of GelSight that can register physical features less than a micrometre in depth and about two micrometres across.

Moreover, because GelSight makes multiple measurements of the rubber's deformation, with light coming in at several different angles, it can produce 3D models of an object, which can be manipulated on a computer screen.

Traditionally, generating micrometre-scale images has required a large, expensive piece of equipment such as a confocal microscope or a white-light interferometer, which might take minutes or even hours to produce a 3D image. Often, such a device has to be mounted on a vibration isolation table, which might consist of a granite slab held steady by shock absorbers. But Adelson and Johnson have built a prototype sensor, about the size of a soda can, which an operator can move over the surface of an object with one hand, and which produces 3D images almost instantly.