Inside the innards of a nuclear reactor

By By Jennifer Chu, MIT News Office | 22 Jul 2011

As workers continue to grapple with the damaged Fukushima Daiichi nuclear powerplant in Japan, the crisis has shone a spotlight on nuclear reactors around the world. In June, The Associated Press released results from a yearlong investigation, revealing evidence of ''unrelenting wear'' in many of the oldest-running facilities in the United States.

|

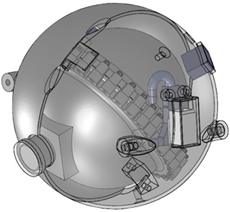

| A spherical robot equipped with a camera may navigate underground pipes of a nuclear reactor by propelling itself with an internal network of valves and pumps. Image: Harry Asada/d'Arbeloff Laboratory |

''We have 104 reactors in this country,'' says Harry Asada, the Ford Professor of Engineering in the Department of Mechanical Engineering and director of MIT's d'Arbeloff Laboratory for Information Systems and Technology. ''Fifty-two of them are 30 years or older, and we need immediate solutions to assure the safe operations of these reactors.''

Asada says one of the major challenges for safety inspectors is identifying corrosion in a reactor's underground pipes. Currently, plant inspectors use indirect methods to monitor buried piping: generating a voltage gradient to identify areas where pipe coatings may have corroded, and using ultrasonic waves to screen lengths of pipe for cracks. The only direct monitoring requires digging out the pipes and visually inspecting them - a costly and time-intensive operation.

Now Asada and his colleagues at the d'Arbeloff Laboratory are working on a direct monitoring alternative: small, egg-sized robots designed to dive into nuclear reactors and swim through underground pipes, checking for signs of corrosion. The underwater patrollers, equipped with cameras, are able to withstand a reactor's extreme, radioactive environment, transmitting images in real-time from within.

The group presented details of its latest prototype at the 2011 IEEE International Conference on Robotics and Automation.